Knowledge & Tips

How to Choose a Suitable Air Compressor for Your Application?

There are many brands of air compressors in the market. Many customers really don’t know how to choose a suitable air compressor. In fact, while choosing an air compressor, customers should consider these important fectors: the brand of air compressor, the price of air compressor, and the suitability of the machine application which should cope with the end use scenarios such as the power supply (voltage, frequency), FAD-free air delivery capacity, ie CFM or m3/min, the pressure level (Bar or Psi) and the power level (Kw/horse power), and buyers should also consider the after-sales service. Here let Chengdu Pudding Mechatronic Co. CPMC provide the practical advice for customers to select an ideal air compressor. CPMC is growing to be one of the largest online distributors (wholesaler) in China. CPMC main goal is to provide competitive prices and professional services for overseas buyers.

The air compressor selection follows the following principles

1) Scientific Planning

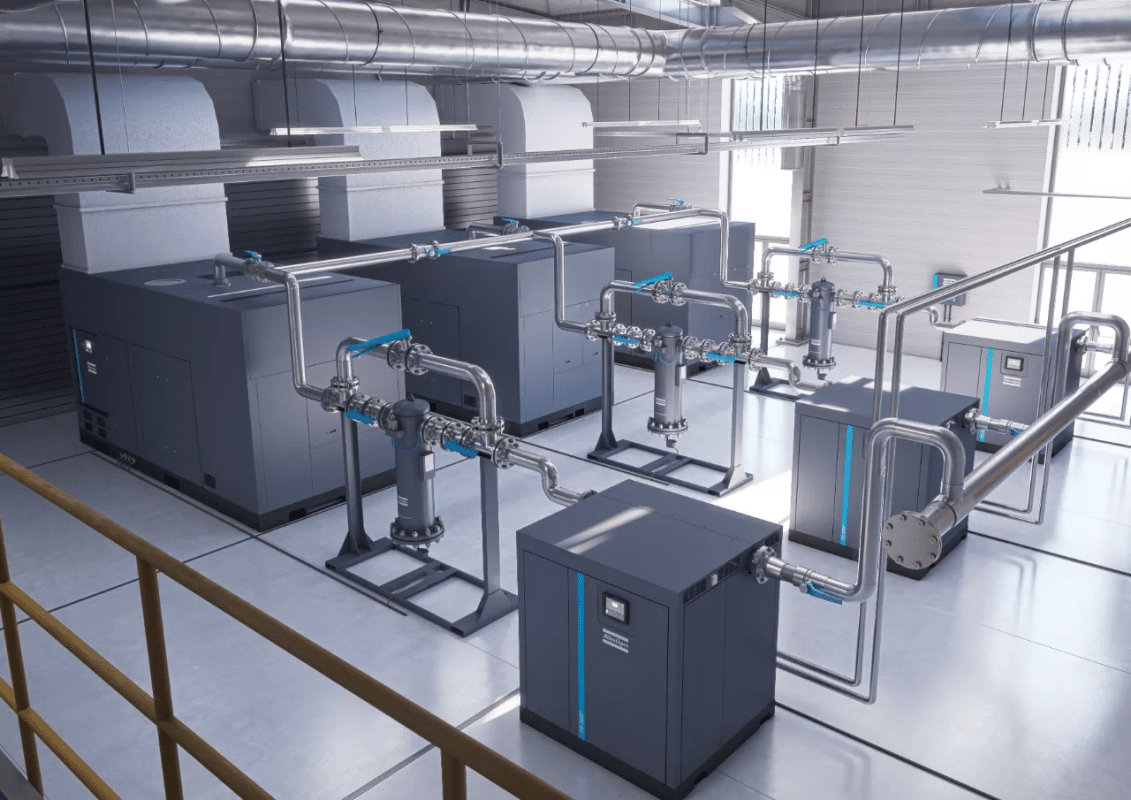

The size and number of air compressors must be carefully calculated and determined. Post-processing equipment is not as much as possible, but configured as needed. The equipment room should be located in a clean and well-ventilated place as far as possible, preferably away from dust. The pipeline layout should minimize elbows and joints, and the pipe diameter selection should be reasonable.

2) Air Power Consumption Planning

- 1. The capacity of the air compressor is too large, resulting in a high waste of no-load energy of the air compressor.

- 2. Too many filters are installed, the pressure loss is large, and the energy waste is high.

- 3. The air compressor is not a centralized gas supply, but is distributed throughout the plant, with independent pipelines, which increases the cost of equipment purchase, and also increases pipeline costs and operation and maintenance costs.

- 4. The ambient temperature of the air compressor room is too high, which is equivalent to reducing the efficiency of the air compressor, reducing the exhaust volume and increasing energy consumption. Every 100°C increase in ambient temperature is equivalent to a 3% reduction in the efficiency of the air compressor.

- 5. Unreasonable pipeline layout, too many elbow joints, increase pressure loss.

3) System Control and Management

- 1. The outlet pressure value of the air compressor is set too high, resulting in increased energy consumption and waste. Each pressure increase of 1kg/cm2 increases energy consumption by about 6%.

- 2. Multiple air compressors can be loaded and unloaded at the same time or capacity adjustment (partial load) operation at the same time, which increases energy waste;

- 3. The machine is poorly maintained or overdue without maintenance, minor faults accumulate into major failures, and the life of the machine is artificially shortened.

- 4. The environment of the engine room is too dirty, causing frequent replacement of air compressor filters, oil filters, oil and gas separators and cooling oil.

- 5. The precision filter of the pipeline is not replaced in time, resulting in large pressure loss and serious energy waste.

- 6. The pipeline is leaking serious and unknowingly, a newly-purchased air compressor is used to supplement the insufficient air volume, resulting in waste. Calculating with a leakage point of 7kg/cm2 10mm, assuming that the electricity fee is RMB 1/kWh, 8000 hours a year will waste 320,000 RMB in electricity bills.

- 7. Try to let the air compressor run at full load to reduce no-load time.

- 8. Regular maintenance to extend the life of the machine.

- 9. Maintain a clean environment in the computer room, and check leaks in time.

4) Purchase of Equipment

When calculating on a ten-year service period, the purchase cost of air compressor equipment accounts for about 5-10%, the maintenance cost accounts for about 5-10%, and the power consumption cost accounts for about 80-90%. Therefore, the work of the machine must first be considered when purchasing–the Efficiency, ie the energy saving means making money, and the operational stability and ease of maintenance are also important factors to consider. Pay attention to the quality of the supplier’s after-sales service. The outlet pressure of the air compressor is set as low as possible, just enough.

Common Unreasonable Phenomena in Air Compressor Systems

The purchase of air compressor is unreasonable.

- When purchasing, only consider the low price of the machine. When using it, it is found that the quality is too poor, the operation is unstable, and the downtime of the failure is long, which causes the loss of production downtime.

- When purchasing, only the operation stability and purchase cost are considered, and the use cost of the air compressor itself is ignored, which causes huge waste over time.

- When purchasing, the supplier’s after-sales service quality is ignored, troubleshooting cannot be delivered in time, and the inconvenience of parts procurement has caused unnecessary losses.

In short, we recommend that you plan to purchase and use air compressor equipment in a professional way.

- 1.Comprehensive consideration of equipment efficiency, operational stability, maintenance convenience and after-sales service quality.

- 2. Choose a professional equipment supplier for overall planning.

- 3. Use and manage air compressors scientifically.