1616747282: O.F.S. I-42 – Atlas Copco China Supplier

$70,000.0 Original price was: $70,000.0.$33,230.0Current price is: $33,230.0.

If you want to learn more about “1616747282: O.F.S. I-42 – Atlas Copco.” air end for Atlas Copco, here you are lucky to be o the right place. Based in China, Air Compressors Trade Service company provides the instant and most competitive prices from our Atlas Copco Wuxi Factory.

1616747282: O.F.S. I-42 – Atlas Copco China Supplier

- Price: Negotiable

- Brand: Atlas Copco

- Condition: New Warranty: 3 months – 1 Year (subject to Atlas Copco Policy)

- After Warranty Service: Video technical support, Online support, Spare parts (per Atlas Copco Policy)

- Place of Origin: Belgium / Wuxi, Jiangsu Province, China

- Application: Atlas Copco Compressors

- Part Number: “1616747282“, “1616-7472-82”, “1616 7472 82”

- Package: Wooden case packing

- Delivery time: 10-45 working Days

For the Atlas Copco oil-free stage air end China promotional prices and the air end availability and delivery time, please contact us now.

Enquiry for: 1616747282: O.F.S. I-42 – Atlas Copco China Supplier

Overview

Product description

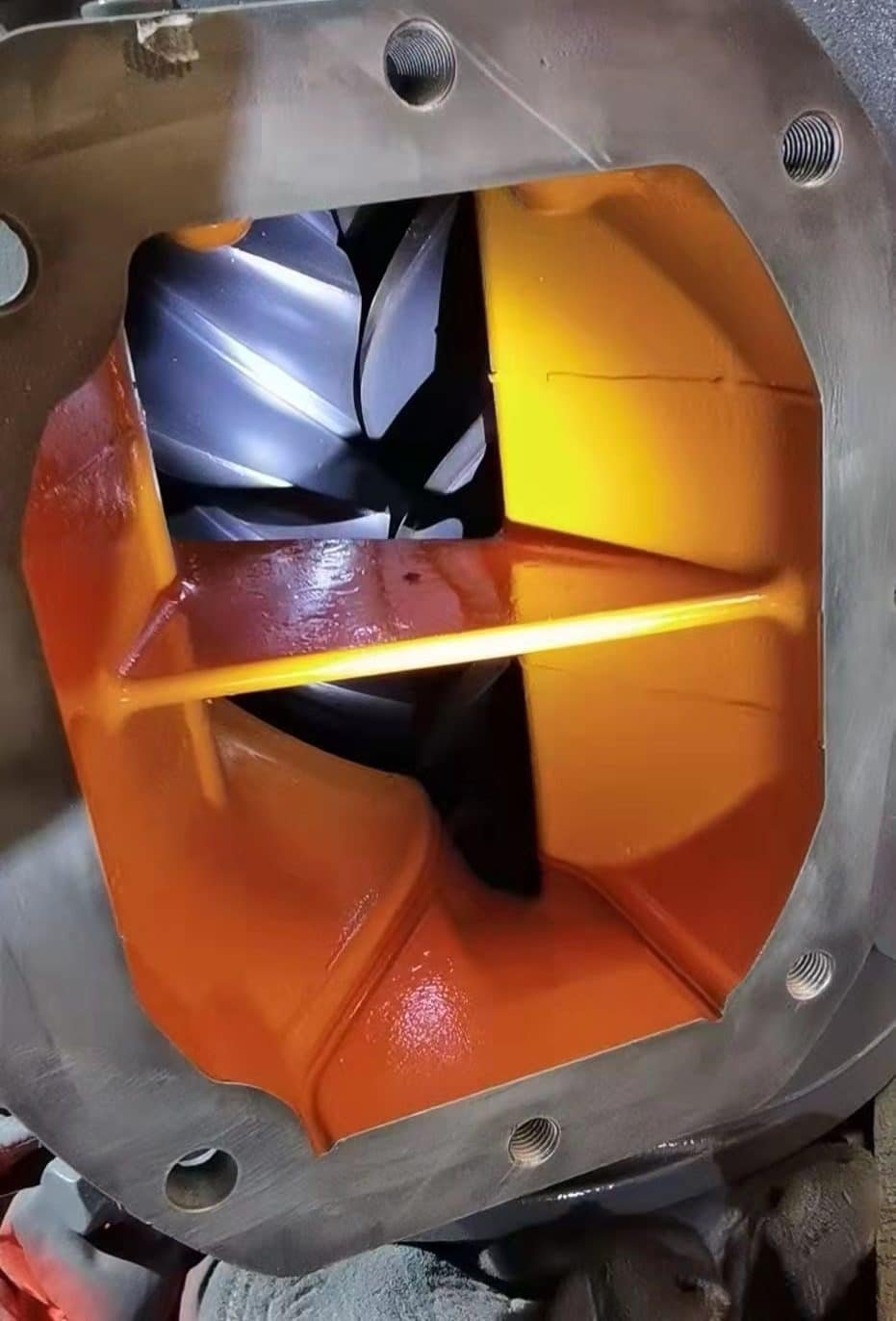

The GA screw compressor of Atlas Copco has good machining accuracy and low noise. With its advanced x-tooth shape, the impact, vibration and noise of the machine are reduced to the greatest extent, so as to effectively prolong the service life of moving parts. For example, the noise of 100hp is only 68 dB (within 1 meter), which indicates that the moving parts of the compressor have high processing accuracy, low noise, good material, low impact and vibration, and long service life of the whole machine, which actually reflects the design and processing level of the machine

Product features

1. Agma13 stage gearbox. The gearbox of Atlas Copco Compressor adopts agma13 manufacturing standard, which is the highest level in the world (the same as the gearbox on Airbus), which can ensure that the speed increasing gearbox will not be damaged under any working conditions.

2. The trouble-free time and service life of the main engine rotor largely depend on the service life of the bearing. Atlas Copco bearing is a bearing specially equipped for our company by SKF company. The service life is 30% longer than that of ordinary bearings and the design service life is up to 150000 hours.

Copco patented high precision 4:6 asymmetric helical rotor with the same diameter and longer length. Other brands mostly use 5:6 asymmetric helical rotor, which is 0.8-1m3/min higher than atlas air compressor of other brands

Product advantages

1. High machining accuracy

2. Agma13 stage gearbox

3. Long bearing life

Product parameters

The filtration efficiency is more than 99.5%

matters needing attention

1. Before starting the new machine, check whether the bearing, coupling and other parts are in good condition

2. Check the steering when starting up or replacing the cable.

When you import physical things from a country far from home, we are sure that you are concerned about the Packing, Shipping and Delivery reliability and efficiency. To work with Air Compressors Trade (Chengdu Pudding Mechatronic Co.CPMC Sichuan, China), you can feel worry free for each and every of your orders with us. Once purchase payment done, our staff will keep an eye on your orders to ensure it is in the right process. And we will stay in touch closely via phone calls, WhatsApp, WeChat and Emails. Thank you for the booking.

Chengdu Pudding Mechatronic Co. CPMC was established with a vision to provide international buyers competitive prices for world famous air compressors and the related GENUINE ORIGINAL spare parts, air tools, woodworking tools & hardware products with professional consultancy and sales service. Based in China and running our own network AirCompressorsTrade.Com, we consistently strive to become one of the most influential DIRECT online supplier rather than those middle handlers on third platform like Alibaba, Made-in-China or Globalsources, Ebay, Amazon or Shopify.

CPMC China Air Compressors and Genuine Original Parts Business Divisions:

Our business main 3 lines

- Compressors +Air Dryers of all types & models for Atlas Copco, Sullair, Ingersoll Rand, Doosan, CompAir, GD, etc and China Local Brand;

- “Genuine Original parts“ for above brands for stationary compressors and portable mobile compressors; Vacuum Pumps and Original Parts; And OEM or replacement parts per clients request;

- Second hand equipment of air compressors and air end, motors, etc.

CPMC China service team work closely with many world reputable manufactures, and the related OEM factories, inner Chanel resources home and abroad. International buyers can expect better prices from us than purchasing from third party platforms, meanwhile we ensure “Genuine products” with reliable delivery.

World Famous Air Compressors we deal:

- Atlas Copco

- Sullair

- Ingersoll Rand

- CompAir

- Doosan

- Gardner Denver

- Chicago Pneumatic

- Quincy

- Kaeser, etc

Chinese Giants of air compressors and spare parts:

- Kaishan

- East Asia – Jaguar Air Compressors

- Hongwuhuan – Red Five Rings

CPMC China compressors, Genuine Spare Parts, and Tools Worldwide Market

About China Chengdu Pudding Mechatronic Co., CPMC (Legal notice)

Chengdu Pudding Mechatronic Co., CPMC is an independent supplier offering Air Compressors and Genuine Original Parts, or OEM parts and/or aftermarket products (per client’s request) for international buyers. Our mission is to provide overseas buyers with quality air compressors, related parts, air tools and woodworking tools with discounted offers. However CPMC is not affiliated with most manufacturers mentioned on this website. Genuine Original Parts or the Original Equipment Manufacturer’s trademarks belong to each manufacturer. AirCompressorsTrade.com makes no claims of special affiliation with or special sanctions by the original manufacturers or the respective trademarks.

Only logged in customers who have purchased this product may leave a review.

Here are the answers to the frequently asked questions from our customers abroad. Should you have any further questions or concerns on air compressors, spare parts, tools, welcome to leave your questions. Our sales consultants will try best to address every of your concerns. Thank you for choosing Chengdu Pudding Mechatronic Co.,CPMC (成都沛丁机电设备有限公司/Chengdu Peiding Mechatronic Co., Ltd.)

购买常见问题

We have been trying best to bring the most competitive prices to our international buyers, however some of our online prices are probably not updated for quite a while and our factories may increase or decrease our distribution prices without prior notice far in advance. So if you feel you may get a cheaper price for a designated compressor or spare part, please send us detailed requirements with specifications such as name plate, parts numbers, pictures, etc. We will answer you with great prices via email SOON.

Yes, of course, we double check all the specified items you purchase from us before and during the packing. Further more, if requested, additional insurance can be inclusive for the China mainland and/or international shipping.

Yes, please provide the detailed and exact address, contact person, phone number and the appropriate time for picking up.

Yes, we can ship your goods to your designated Amazon/Europe warehouse, or even deliver to your door as well.

We accept T/T, Western Union, WeChat Pay, Alipay, PayPal, Credit Card with 3-4.5% fee.

You can pay us by bank telex transfer (T/T), Western Union, PayPal and so on. However, like any online international gateway B2B or B2C websites which normally surcharge 2% as transaction fee both on buyers and suppliers together, the banking fee and the transaction fee for your purchase with us may apply (This small fee is cheaper and it is subject to vary via different payment gateway, 1-2%). Some buyers have Alipay or WeChat pay through their friends or agent in China, this is really convenient and also cheap way to pay us. However we suggest the T/T or western Union agent transfer. For Credit card payment, there would be 3-4.5% surcharge on top of the quotation.

Yes, we have been working in international trade business for years. We have a bunch of shippers/ forwarders and companies all of which have all necessary export licenses thus we can provide the customs declaration and ship the goods out to you. We are able to provide you the competitve quotation based on incoterms FOB, CIF to DDP, etc.

We have been in air compressors and spare parts sales and services for nearly 5 years. We know the China domestic and international markets and the products quality level in the field. We know how competitive we can be during and after the COVID19 world wide situation. All our sales service staff have working experiences in selling air compressors, spare parts and industrial tools on Alibaba or AliExpress.

Please be patient to expect your package which should arrive safely according to schedule in regular basis, however the worldwide COVID19 is still unstable in some regions of the world, and this may infect the China international shipping time. If this product is for virus protection purposes and if the coronavirus (COVID-19) will affect your purchase delivery, it will, anyhow, get to you after the necessary custom procedure.

Feel free to ask your questions you may have, and we will update our answers in couple of hours generally.

Thank you for contacting us, China Pudding Mechatronic Co.CPMC Service team will get back to you in 0.5-23.5hours!

Reviews

There are no reviews yet.